What’s the best form of charcoal? Hardwood lump charcoal? Charcoal briquets? Wood embers? Extruded charcoal? Japanese binchotan?

A lot of cooks swear by one fuel or another with vehement conviction, but I’m here to tell you, it is all much ado about little. The quality of the raw food is far more important. The seasonings are far more important. And without a doubt, getting food off the heat at the right internal temp is far more important. (See my Food Temperature Guide). You can spend a lot on expensive charcoal. Save your money and get a good thermometer (see my buying guide to thermometers).

The secret to successful cooking is controlling variables, the most important of which is heat. Your goal is to get a fuel that burns the same this Sunday as it did last Sunday and control it.

Cut to the chase

Here’s a look at the different types of charcoal, their pros and cons, and why we recommend briquets. Also there’s a discussion of wood types, and how to set up a grill in the essential 2-zone system. Click here for more about the science of smoke and wood.

We’ll talk about the issues in detail in a minute, but here’s the bottom line: Harry Soo of Slap Yo Daddy BBQ, one of the top 10 competition teams year in and year out once told me “I buy whatever is on sale.” Mike Wozniak of Quau, the 2010 Kansas City Barbeque Society Team of the Year and winner of scores of big money championships told me “Charcoal is for heat, not flavor. Wood is for flavor. I cook on whatever brand the competition sponsor is giving away for free.” Let’s find out why.

The science of charcoal

Good charcoal is mostly pure carbon, called char, made by cooking wood in a low oxygen environment, a process that can take days and burns off volatile compounds such as water, methane, hydrogen, and tar. In commercial processing, the burning takes place in large concrete or steel silos with very little oxygen, and stops before it all turns to ash. The process leaves black lumps and powder, about 25% of the original weight.

When ignited, the carbon in charcoal combines with oxygen and forms carbon dioxide, carbon monoxide, water, other gases, and significant quantities of energy. It packs more potential energy per ounce than raw wood. Char burns steady, hot, and produces less smoke and fewer dangerous vapors.

The process of making charcoal is ancient, with archaeological evidence of charcoal production going back about 30,000 years. Because charcoal burns hotter, cleaner, and more evenly than wood, it was used by smelters for melting iron ore in blast furnaces, and blacksmiths who formed and shaped steel. Commercial production was first done in pits covered with dirt by specially trained craftsmen called colliers. Yes, your friend named Collier probably had an ancestor who made charcoal for a living.

Lumps vs briquets

Let’s look at the differences between lump and briquets. One has to be careful about generalizations here because each brand is different. Kingsford Original “Blue Bag” is the most popular and it has “natural” binders such as cornstarch.

If you are concerned about additives then buy one of these: Kingsford 100% Natural Hardwood Briquets, and B&B Competition Oak Briquets. They claim to use nothing but hardwood. You might also try Royal Oak 100% All Natural Hardwood Charcoal Briquets. They say it has only vegetable starch as a binder. Alas many of these are not widely available.

Below is Part 1 of a great video sequence by Van Wagner about how colliers made hardwood charcoal in Pennsylvania from the 1600s to the mid 1800s, and how you can do it yourself if you are so inclined. Click here for Part 2, Part 3, and Part 4.

https://youtu.be/RxW7g3IwD1k Making charcoal is still practiced at home in third world economies such as Haiti. Below is a fascinating 10 minute video of how to make charcoal briquets from agricultural waste by Amy Smith of D-Lab at MIT. She uses spent corn stalks and an old oil drum.

Lump charcoal

Lump is the next best thing to cooking with wood and it is fashionable for the same reasons that “organic” food is fashionable. It has this aura of being more natural. There are more than 75 brands and some are even varietal: Cherry, mesquite, coconut shell. I have cooked with many of them. For definitive ratings and reviews of lump charcoal, visit Doug Hanthorn’s website, a.k.a. the Naked Whiz.

Lump charcoal is made from wood scraps from saw mills and from flooring, furniture, and building materials manufacturers. Branches, twigs, blocks, trim, and other scraps are carbonized. Every brand is different. Some swear they use no building materials. The result is lumps that are irregular in size, often looking like limbs and lumber.

Benefits of lump

Lump leaves less ash than briquets because there are no binders. This is important in some kamado smokers such as the Big Green Egg which don’t have a lot of room for ash to collect during long cooks without blocking airflow. The big disadvantage is that lump is harder to find, more expensive than briquets, burns out more quickly, varies in BTUs (heat output) per pound (and thus, per cook), varies in wood type from bag to bag, varies in flavor from bag to bag, and often bags of lump contain a lot of useless carbon dust from improper filtering in the factory and rough handling in the stores. Some lumps can be quite large and don’t fit neatly in charcoal chimneys, the best way to light charcoal.

As a result, one never knows exactly how much fuel you have in a chimney. On the other hand, the bags are lighter and easier to handle. This is because the lumps are irregularly shaped, so there is more air in the bag.

Barbecue lore says lump burns hotter than briquets, but the AmazingRibs.com science advisor Prof. Greg Blonder says “Hotter depends on how the coals are arranged. Because of their irregular shapes, they can nestle together like puzzle pieces and impair airflow which can reduce heat.” Some lump can be quite large and create hot spots in the grill so food cooks unevenly. Lump can contain more charcoal powder and crumbs which can fill the gaps between chunks and stifle airflow and make the fire burn cold. Remember air is as important as is the charcoal. So, I recommend that you discard the dust at the bottom of the bag.

Myths about lump

The folks at Cooks Illustrated also found this to be a myth (click the link for their research). They took two typical six quart chimneys and filled one with lump and one with briquets. They fitted two identical grills with seven digital thermometer probes each, and learned that by volume, not weight, and volume is how most of us measure charcoal, especially if we use a chimney, the two burned about the same – for about 30 minutes – but after that the briquets held heat longer and the lump turned to ash faster. Then they repeated the test 11 times. Of course this only matters if you are seeking high heat. You can reduce the temp by reducing the amount of charcoal or the amount of oxygen.

Is it more flavorful?

Another myth is that lump has more flavor. Not if it is properly made. If all the wood is completely carbonized, converted to char, the flavor will be little different from other charcoal: Close to neutral. But often lump is not thoroughly carbonized. As you will notice, a bag can have large chunks, softball size, and small chips, golfball size or smaller. Often some of the larger chunks still have cellulose, lignin, and other wood components left in their centers. And when they burn they spark and smoke and give off a pleasant smoke flavor. This can be a nice addition to your food, but it isn’t controllable. You don’t know from one meal to the next what wood flavor and how much you’re getting.

Top pitmasters prefer to control this by burning pure charcoal and then adding wood of their choice in the quantities of their choice to produce the quantity and quality of smoke they prefer. Here is a 9 second video of Fogo brand lump charcoal sparking like mad in a chimney starter. Fogo is one of the top rated brands of lump.

Finding trash in your charcoal

Finally, it is not uncommon to find rocks, metal pieces, and other foreign objects from the lumber operations where the wood is gathered. The picture here shows some PVC pipe and nylon rope found in a bag of lump by Thad Barnes of Austin, TX. Mmmmm, you gotta love the idea of plastic soot on your meat.

Below is a part of a computer cable found by another reader in a bag of lump. He contacted the manufacturer, who responded with a form letter. It said, in part “It is not standard for ANY foreign materials to make its way into the charcoal, however being products of a natural environment, occasionally it does happen. Charcoal is very dirty and the powder covers everything. Our screening system may have missed this item and we sincerely apologize.” This letter makes me laugh. How is a computer cable “products of a natural environment”? And you say “our screening system may have missed this item”? May have? And you say “Charcoal is very dirty and the powder covers everything.”

Perhaps it would be easier to catch foreign materials before they go into the cooker, when a nice shiny metal object would surely stand out from chunks of wood? Above all, if it is “not standard” why do you have a form letter for responding to complaints of foreign objects?

Here is a piece of rope another reader found in his bag.

What this all means

All this makes me fear that some of the wood used to make lump could be chemically treated lumber. Common wood preservatives are creosote, chrome, copper, pesticides, fungicides, and arsenic (now illegal but found in plenty of scrap from building demolitions). The process of making charcoal is not government regulated or supervised in any nation that I know of, and quality control in Thailand might not be the same as in California.

All these concerns to the side, if I am cooking something hot and fast, like flank steak or skirt steak or fish, I often reach for lump because it often puts out smoke. But for thick steaks, chickens and anything low and slow like ribs, I prefer briquets.

Charcoal briquets

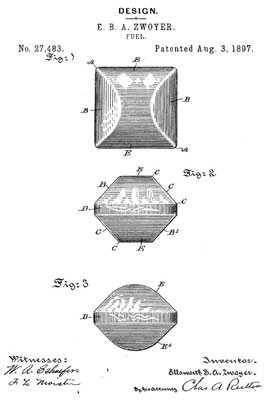

Patented in 1897 by Ellsworth Zwoyer, the briquet really took off when, in the 1920s, Henry Ford, in collaboration with Thomas Edison and EB Kingsford, made lots of them from sawdust and wood scraps from Ford’s Detroit auto plants. Cars bodies were made with a lot of wood in those days. So Ford not only brought the world affordable cars, he created an industry that made backyard barbecue easy.

The company was later sold, and today Kingsford, a division of Chlorox, converts more than one million tons of wood scraps into briquets a year. There are five plants in the US. I visited the one in Belle, MO.

How they’re made

Kingsford briquets begin as sawdust and chips from mixed woods from timber mills. Kingsford claims their mills don’t make treated lumber and they are inspected by Kingsford quality control people to make sure there is not too much softwood. The sawdust arrives by truck and piled up in a mountain range. Moisture level is about 50%. A bulldozer pushes it into a conveyor that separates large chunks and foreign matter like rock.

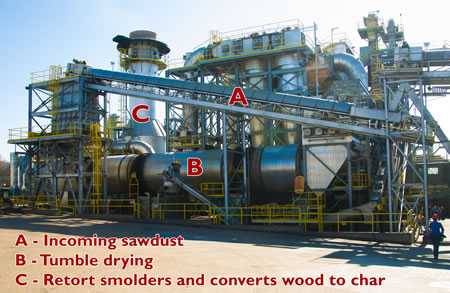

The sawdust arrives in a conveyor (A) and then enters a huge rotating barrel (B) for tumble drying that takes the moisture down to about 35%.

Then it goes into special ovens called retorts (C). This is where the magic happens. With little air in the retort, the wood burns down to char, and comes out at about 25% of the weight that went in. The process drives off a lot of combustible gases that are used to generate energy for running part of the plant. Talk about a green industry: Using the waste (sawdust) of a renewable energy source (trees), and using energy generated by the charring process to run part of the manufacturing operation.

Additives

Once the char is cooked it is crushed. For the standard “blue bag” Kingsford it is and mixed with small amounts of additives act as binders, improve ignition, promote steady burning, and make manufacturing more efficient. They are anthracite coal (It has the highest carbon content, the fewest impurities, and the highest energy density of all types of coal), mineral charcoal (a form of charcoal found in coal mines), starch (you eat starch all the time), sodium nitrate (a salt used in ham, hot dogs, etc.), limestone (a sedimentary rock composed mainly of skeletal fragments of marine organisms such as coral), borax (a natural mineral found in water used to to help it release from the presses), and sawdust. All these components can be found in nature.

If these additives make you nervous, and I don’t think they should, other charcoals have fewer additives. My favorites are Kingsford 100% Natural Hardwood Briquets and Weber which is said to be 100% hardwood, no additives.

The slurry is then molded into their pillow shape. In the photo here, strips of the pillows are coming off a roller onto a conveyor belt. They are then dried, bagged, stacked, and shipped. The Kingsford Belle plant runs 24/7 and produces an average of 550 tons per day. That’s more than 61,000 of the 18 pound bags from this one plant per day.

Common complaints

Briquets with binders typically produce more ash than hardwood lump since they contain more non-combustible materials. Some cooks complain about these additives, but there’s a lot to be said for a fuel source that is rock solid consistent from bag to bag. Here’s a really useful rule of thumb: There are about 16 Kingsford briquets in a quart, and 64 in a gallon. A Weber chimney holds about 5 quarts, or about 80 briquets. That’s a measured quantity of BTUs. There are too many variables in outdoor cooking, and having a reliable steady heat source is crucial. Charcoal is easy to light with chimneys and I highly recommend them. Click the link to see how easy they are and what other charcoal lighting options are available.

Some folks say they can taste the additives in their food. I can’t, and in a previous career I was a pretty well known wine taster, won championships, and served on the US wine tasting tream once. Self-igniting Match-Light charcoal, which has mineral spirits added to promote ignition, is a different story. Kingsford and government regulators say it is safe if you follow instructions, but I think they can taint the food. I don’t use the stuff and I don’t recommend it.

The real issue

The biggest problem with charcoal, both lump and briquets, is that they can produce an odd flavor before they are fully ignited, i.e., before they are coated in white ash and barely smoking. This is caused by gases escaping before they are combusted. Most people cannot smell or taste it (I cannot), but even if you can’t you should always work with fully lit coals. This means that the temp starts off at a stable temp and slowly declines. That’s more predictable that starting off and getting hotter and then declining. This means that if you use the Minion method or a fuse system, you may encounter this problem.

Briquet experiments

In January 2022 The Virtual Weber Bullet website published the results of experiments comparing three briquets: Kingsford Origina, Franklin Barbecue, B&B Competition Oak Charcoal Briquets. They concluded:

Kingsford lit faster than Franklin and B&B. It also appeared to burn hotter. B&B burned longer than the others, and Franklin produced the fewest ashes by both weight and volume. B&B produced the most ashes by volume. Kingsford produced the most ashes by weight and as a percentage of the pre-burn weight.

New and exotic products

Superstar chef Dan Barber of Blue Hill at Stone Barns up the Hudson Valley from New York City is making charcoal from animal bones for use in his restaurant. The final product, shown here courtesy of the restaurant, is eerie, retaining its original shape, but black. One can order a pork chop grilled over charcoal made from pork bones.

Binchotan is a traditional charcoal made from ubame oak in Japan and Vietnam and is called “white charcoal” because it is shiny. Typically it comes in the form of slender brittle branches, 1 to 2″ in diameter and 6″ or so long and makes a metallic ring when the sticks are banged together. Japanese restaurants often import it at great expense and market the fact that they use it. They promote the fact that it is flavorless.

In Asia, coconut wood, ground to sawdust is compressed and extruded in 3″ diameter logs, then carbonized, and cut into briquets. And no, it doesn’t taste like coconut.

Charcoal flavor

It has become fashionable among people interested in the science of cooking and readers of Modernist Cuisine by Nathan Myhrvold to say that there is no difference in flavor between charcoal and gas because a perfect charcoal burn produces little or no smoke, and all grilling flavor comes from the vaporization of drippings.

In practice, however, there are few perfect burns. To be flavorless, the coals must be fully ignited and burning at high heat. This requires a balance of coals and oxygen so if the intake vents aren’t fully open or if there are too many coals for the vents to supply, there will be smoke. Smoke is made of microscopic particles and gases. Particles will settle on food and flavor it and gases will combine with the compounds on the food’s surface and create new flavors.

In practice, charcoal produces some smoke. If the coals are not yet fully ignited at the start of a cook, if new coals have been added to the fire, there will be smoke. In the case of lump charcoal, the lumps aren’t always perfectly carbonized meaning there is can be wood remaining. If there is uncarbonized wood, and there almost always is, it will combust and produce smoke and flavor.

Both charcoal and gas grills produce combustion gases that impart flavor.

Other factors

Temperature is also a factor. Charcoal usually transmits more heat that the normal gas grill, and this creates more browning on meat, and browning, the maillard reaction and caramelization, produce huge flavors.

Time is also a factor. For a quick cook of thin food, smoke and gases have little impact. For longer cooks, there is a cumulative impact.

So the theory holds that a balanced burn of pure charcoal and adequate oxygen will produce little or no flavor without drippings. But in practice, that is rarely the case.

Mesquite or hickory charcoal?

Charcoal is mostly pure carbon plus additives. So, the wood from which it is made will make little noticeable difference in flavor or burning temperature. To get wood flavor, you need to add wood to the fire. Some charcoal comes with wood molded into it. It creates smoke nicely. I prefer to manage how much smoke and when by adding it myself. Read The Science of Wood for how this is done.

So which is best?

Remember, charcoal is for heat, not flavor. If you want flavor, it will come from vaporized drippings, laden with fats, sugars, and proteins, or from wood thrown on the coals, not to mention spice rubs, injections, marinades, and sauces. Watch the superb closeup slowmo video from the food scientists at ChefSteps.

Consumer Reports has weighed in on the subject and they agree with me.

Ash in your garden

You might be staring at the ash from your charcoal and wondering if it could enhance the soil of your garden. I asked the AmazingRibs.com science advisor Prof. Greg Blonder who said “Wood ash is fine. Google ‘garden advice fireplace ash’, but I would stay away from charcoal briquet ash. Too many ingredients, and even if one brand was fine today, they might change the formula tomorrow.”

Spontaneous combustion?

Some fire prevention websites continue to spread the myth that charcoal, even wet charcoal, can burst into flames when stored.

Doug Hanthorn of the Naked Whiz did some excellent sleuthing and discovered that the origin of the myth was a government warning about the storage of coal, not charcoal. Fire safety scientists have investigated and concluded that “Spontaneous combustion of bagged charcoal briquets in commercially available sizes is impossible under any normal ambient conditions.”

But once a myth gets started it can travel like brush fire and stamping it out is nigh impossible.

Bottom line

My best advice? Briquets give me consistency as well as better temp and flavor control and I’m all about control when I cook. Eliminate this variable and pick one consistent brand of briquet. Learn it, and stick with it for a year until you have all the other variables under control. If binders bother you go for Wicked Good 100% All Natural Hardwood briquets, Kingsford 100% Natural Hardwood Briquets, Weber, B&B Briquettes, Royal Oak, and Duraflame Sear Pro briquets. Remember, the quality of the raw food, salt, rub, sauce, wood smoke, cooking temp, and serving temp far outweigh the impact of charcoal on outcome.

High quality websites are expensive to run. If you help us, we’ll pay you back bigtime with an ad-free experience and a lot of freebies!

Millions come to AmazingRibs.com every month for high quality tested recipes, tips on technique, science, mythbusting, product reviews, and inspiration. But it is expensive to run a website with more than 2,000 pages and we don’t have a big corporate partner to subsidize us.

Our most important source of sustenance is people who join our Pitmaster Club. But please don’t think of it as a donation. Members get MANY great benefits. We block all third-party ads, we give members free ebooks, magazines, interviews, webinars, more recipes, a monthly sweepstakes with prizes worth up to $2,000, discounts on products, and best of all a community of like-minded cooks free of flame wars. Click below to see all the benefits, take a free 30 day trial, and help keep this site alive.

Post comments and questions below

1) Please try the search box at the top of every page before you ask for help.

2) Try to post your question to the appropriate page.

3) Tell us everything we need to know to help such as the type of cooker and thermometer. Dial thermometers are often off by as much as 50°F so if you are not using a good digital thermometer we probably can’t help you with time and temp questions. Please read this article about thermometers.

4) If you are a member of the Pitmaster Club, your comments login is probably different.

5) Posts with links in them may not appear immediately.

Moderators