Testing and Rating Cut Resistant Gloves

Published On: 5/22/2019 Last Modified: 6/16/2025

The Best Cut-Resistant Gloves

If you wield sharp blades often, chances are, at some point, you’re going to get cut. No one loves wearing protective gloves, and maybe that’s why hand injuries are the second most common work-related injury in America (overexertion is the first).

According to the U.S. Bureau of Labor Statistics, more than a million emergency room visits come from hand injuries each year. That’s mostly among professionals, but if you’re an accident prone home cook, you might consider sparing yourself some pain (and medical bills) by protecting yourself.

Click Here To Search Our Reviews And Ratings Of Tools, Toys, And Accessories

The newest models of cut-resistant gloves are inexpensive, comfortable, and flexible. Manufacturers routinely put the following disclaimer on their products: “These gloves are cut and puncture RESISTANT, not cut and puncture PROOF.”

Oh yeah? To see just how “cut-resistant” they are, we put some of the best gloves to the test by slicing, gouging, and chopping them. Guess what? We couldn’t cut through any of them. Short of dropping a guillotine on them, most home cooks would have a tough time slicing through the cut-resistant gloves on the market today. However, some gloves were a little less comfortable to work with or didn’t fit quite as well as others. See below for complete reviews and ratings.

What Makes Them Cut Resistant?

Most are constructed with one of two different materials:

- UHWMPE (Ultra-High-Weight-Molecular-Polyethylene), which is marketed under brand names like Dyneema®, TenActiv™, and Spectra®.

- Para-aramid, the technical name for brands such as Kevlar®, XKS®, Aramex®, Rhino®, Metalguard®, Contender™, ATA®, Punkban™, or Armorcore®.

Some glove manufacturers add fiberglass or stainless steel to these materials to create proprietary blends with added cut resistance. As the maker of Superior Gloves says, “It’s like adding rebar to concrete.” Here are some of the material combinations you may come across: Foam Nitrile Coated Kevlar, Rubber Coated Kevlar, Kevlar PVC Dot Knit, Nitrile Durarmor, Knit Kevlar, Kevlar and Leather, Nitrile Coated Kevlar, Composite Filament, Dyneema Stainless Steel Mesh, and Spectra Fiber.

The most expensive gloves include stainless steel mesh. Steel offers maximum protection for meat and poultry workers who deal with sharp knives and heavy whirring blades every work day. Kevlar shows up a bit more often because it’s less expensive, more flexible, and still very cut resistant. Kevlar is the material used in most body armor, bullet proof vests, and other protective gear.

Firefighter gear (PPE or Personal Protection Equipment) often includes Kevlar because this material is both cut-resistant AND heat resistant. (If you’re in the market for heat-resistant BBQ gloves, check out our reviews here.)

Many manufacturers of cut-resistant gloves overlap several sheets of Kevlar reinforced with one or more of the other materials mentioned above. Kevlar-based cut-resistant gloves on the market are virtually identical, apart from brand name and price. When shopping, look past the brand names to the glove’s construction material, and then look for the best price.

A Note on Laboratory Testing

Manufacturers and various regulatory agencies test and rate cut-resistant gloves in several ways. The most popular are the EN388 (European) and ANSI (North American) tests. EN388 tests use a constant weight on a counter-rotating circular blade that is moved back and forth across a sample product by the test machine to see how long it takes to cut through the material. The ANSI test involves a fixed razor blade with three different weight/force levels that attempts to cut through the glove material, again with back and forth slicing.

In the EN388 tests, the top score is 4-5-4-4. The numbers correspond to the highest ratings for abrasion, blade cut resistance, tear resistance, and puncture resistance. Notice that blade cut resistance gets a top score of 5, which corresponds more closely with the American ANSI ratings. If you see an X in an EN388 rating (such as 45X4), the X represents no score and means that the glove was not rated for that particular test (in the case of 45X4, the glove was not rated for tear resistance). A zero (0) in the rating means the glove failed that particular test.

ANSI results are simpler and more direct: Only cut-resistance is tested with ratings from 1 to 5. However, some metal mesh gloves can be scored higher with a rating of 9. We are not sure how this happens.

If you’re curious to know more, Superior Glove, a Canadian glove manufacturer, has a comprehensive blog on everything you need to know about selecting gloves on their website that details laboratory testing methods and materials used in the manufacture of their gloves. This blog provides a huge amount of information about cut, abrasion, and puncture resistant gloves in general.

Real World Testing Criteria

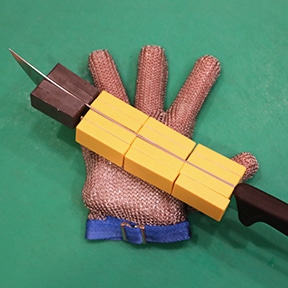

Lab tests are fantastic but we wanted to find out how these gloves performed in the real world, in our hands while cutting food with sharp knives. We began by devising a way to test cut and puncture resistance without removing any of our own digits or necessitating a trip to the local ER.

To simulate the consistency and flexibility of a human hand, we used partially frozen hot dogs (the fingers) and a partially frozen piece of pork belly (the palm). Partially freezing them made them more like human muscles, flexible enough to be positioned and bent but not quite as soft as a raw hot dog.

We inserted the dogs and pork belly into some thin disposable nitrile gloves (so thin you could cut them with a spoon), which served to both maintain the shape of our faux hand and easily reveal any punctures and cuts made during the tests.

We tested the gloves for cut and puncture resistance in several places (fingers, palm, and back of the hand). We tested grip in dry, wet, and greasy conditions. And we assessed comfort, fit, and dexterity.

For the cut resistance test, we had one of our sharpest knives, a Victorinox scimitar, professionally sharpened. We then attempted to cut the faux hand gloves two ways: first with normal blade pressure as the knife was drawn across the hot dog fingers and pork belly palm (as well as the back of the “hand”) multiple times.

Next, we attached several magnetic weights to the knives and tried to cut the gloves again with the additional weight and a relatively consistent pressure on each pass. Finally, we used our faux hand to hold a tomato as we sliced it on a sharp mandolin. To our surprise, every glove passed the cut resistance test with flying colors. There was not a single slice mark on any gloves despite our attempts at increasing pressure.

To check puncture resistance, we performed another test: we stabbed each finger three times with moderate pressure. We then dropped the scimitar’s knife point down from a height of one foot directly onto the fingers, the palm, and the back of the glove. Despite these efforts to ruin the gloves, all of them passed and none lost a hot dog finger or sustained a gash or puncture. Only one glove showed a small indentation in the material from the puncture test, and that was actually a steel mesh glove.

Grip tests were up next. We donned the gloves and tried to cut slices from a cooked roast, first by wetting the knife handle with water to make it slightly slippery, and then by lubricating the knife handle with vegetable oil to simulate the fat and grease that tends to migrate to knife handles when cutting meat. Some gloves did okay; others were a bit slippery.

As for the comfort tests, a few models were a slightly small for those with large hands, even though they were labeled as XL. Nonetheless, all of the gloves were pretty easy to get into and out of, didn’t seem to limit dexterity drastically, and were comfortable, if a tad warm, to wear.

Reviews and Ratings

We tested seven different gloves, each one rated at level 5, the highest EN388 and ANSI rating. Most of the gloves performed extremely well as you can see by the Gold and Silver medals below. You really can’t go wrong with any of the gloves here, but check out the full review for details. You may also pick up some insights from members of our Pitmaster Club, who weighed in with their experience, as quoted in the sidebar.

High quality websites are expensive to run. If you help us, we’ll pay you back bigtime with an ad-free experience and a lot of freebies!

Millions come to AmazingRibs.com every month for high quality tested recipes, tips on technique, science, mythbusting, product reviews, and inspiration. But it is expensive to run a website with more than 2,000 pages and we don’t have a big corporate partner to subsidize us.

Our most important source of sustenance is people who join our Pitmaster Club. But please don’t think of it as a donation. Members get MANY great benefits. We block all third-party ads, we give members free ebooks, magazines, interviews, webinars, more recipes, a monthly sweepstakes with prizes worth up to $2,000, discounts on products, and best of all a community of like-minded cooks free of flame wars. Click below to see all the benefits, take a free 30 day trial, and help keep this site alive.

Post comments and questions below

1) Please try the search box at the top of every page before you ask for help.

2) Try to post your question to the appropriate page.

3) Tell us everything we need to know to help such as the type of cooker and thermometer. Dial thermometers are often off by as much as 50°F so if you are not using a good digital thermometer we probably can’t help you with time and temp questions. Please read this article about thermometers.

4) If you are a member of the Pitmaster Club, your comments login is probably different.

5) Posts with links in them may not appear immediately.

Moderators